Are you in the market for a new Grinder Mixer but cannot decide which is best for you? Our Hammer Mill and Roller Mill Grinder Mixers have different features so you can find what works best for you.

The Hammer Mill Grinder Mixer is perfect for farmers who are versatile. By simply changing the screen, you can easily create different grain sizes for different kinds of livestock. The Hammer Mill Grinders are perfect for the farmer who needs a high capacity of feed. Operating from high power, it creates a more consistent grind for improved feed rations. All farmers know time is of the essence, our Hammer Mill options can produce:

- 10-25 Bushels / Min using the 20” Hammer Mill

- 15-35 Bushels / Min using the 26” Hammer Mill

Refer to the chart below to see how which screen sizes create feed capacities.

Pictured above is the Hammer Mill Grinder Mixer.

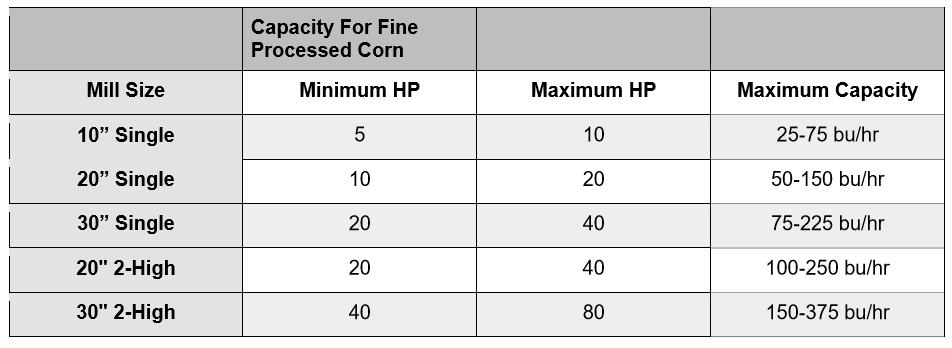

In contrast, the Roller Mill Grinder Mixer operates at a much slower speed than the Hammer Mill Grinder Mixer. This type of grinder produces a more consistent particle size with increased bulk. The variable parameters of the Roller Mill are feed rate, quality of feed, and power to the Roller Mill and roll spacing. The fixed parameters of the Roller Mill are roll corrugations (number per inch and profile), differential roll speeds and roll scrapers. This chart shows how much feed per hour you can expect to produce using the lower horsepower of the Roller Mill options.

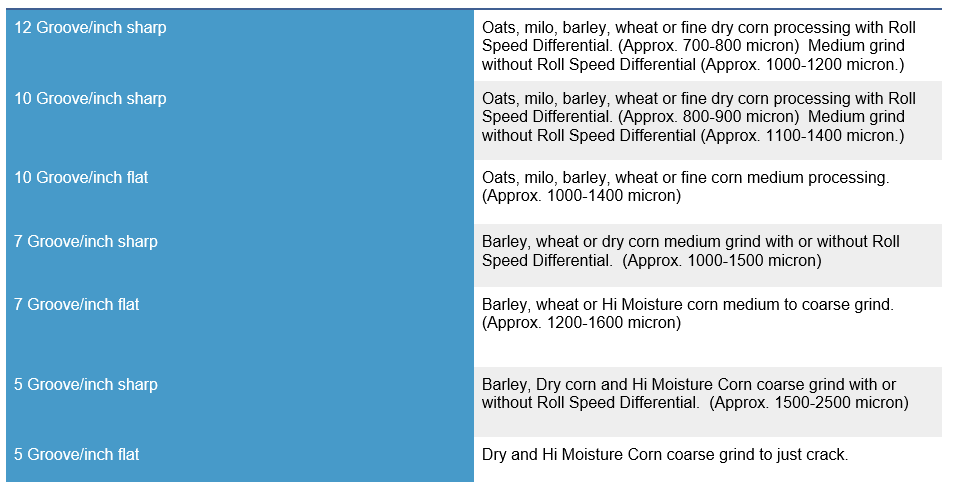

Art’s Way offers both flat tooth grooves and sharp tooth grooves in the 5, 7, or 10 grooves per inch configurations. Flat tooth designs wear better than sharp tooth designs and creates less dust during processing. Sharp tooth designs offer higher capacity ratings than flat tooth designs. The trade-off between flat and sharp tooth designs is quality verses capacity. Flat tooth designs are mainly used for cracking, crimping or flaking grain. Sharp tooth designs are used primarily for grinding powder purposes. The picture below illustrates how different grooves work best for different feed inputs.

This photo illustrates a Roller Mill Grinder Mixer with a flat tooth design.

The above photo shows Roller Mill Grinder Mixer featuring a sharp tooth design. The chart below describes which tooth design works best with each type of feed.

While the Roller Mill and Hammer Mill Grinder Mixer options are there to help you feed your livestock, they both come with different features to help you find what works best for your farming operation. Contact our Customer Service Center today at 712-208-8467 if you have any further questions!